Pipe Line

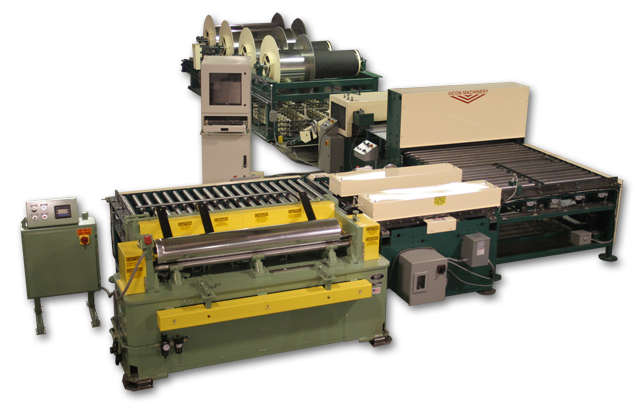

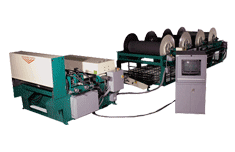

Round Pipe Manufacturing System

The Vicon Pipe Line manufactures precision round pipe sections automatically and fast. Sizes range from 3” to 24” diameter with either the well known reeves or modified lock seams. The Vicon Pipe Line produces profitable duct work.

Reliable performance, high productivity and superior part transfer are just the beginning. The Vicon Pipe Line is backed by our exclusive commitment to provide you with nationwide one-call service, training and support for as long as you own your machine.

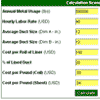

ViSoft Software is menu-driven, user-friendly and can be set to SMACNA standards or customized to your shop standards. Continually updated and supported by Vicon's experienced team of programming engineers, ViSoft ensures enhanced productivity and superb part accuracy.

The precision servo drive on the straightener delivers accurate blanks every time for consistent pipe diameters. Underfed coil cradles provide easy threading and allow a quick change to another coil when needed.

The dual head lock seam roll former automatically sets to the proper location with a servo drive and is controlled by the single input operator console.

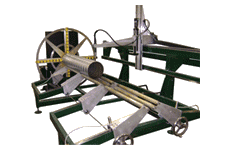

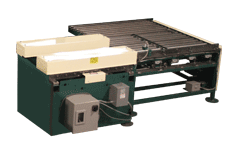

As pipes are completed, the line operator can hold the first piece in place as the part exits the roller, which allows the next part to feed inside the prior piece. This is done repetitiously for nesting and packaging purposes.

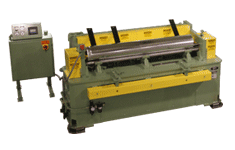

Other machines you might be interested in: